Tips That Nip Drift ~ Mid-South Farmer

Mid-South Farmer, May 2000

A Farm Progress Publication, Mid-South Group®

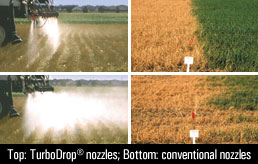

Drifting along with the tumbling tumbleweeds sounds fine in the song, but not for any of the herbicides Jerry Turner, his son, Keith, and his son-in-law, Steve Haywood, spray for their corn, rice, soybeans and wheat near Corning, AR. They say a switch to air-induction (venturi) nozzles greatly increased their spraying efficiency by allowing them to spray a lot of acres in a day with lower drift potential, even on days when small droplets from other kinds of nozzles would drift out of the field.

"That type of technology is better for spraying drift-sensitive herbicides than what we were using," says Ford Baldwin, University of Arkansas Extension weed scientist.

Tom Mueller, University of Tennessee weed scientist, notes results from a study of how well air-induction nozzles work confirm Baldwin's observation. The study was done by one of his graduate students, Robert Etheridge. "Even at spray volumes as low as 5 gallons per acre (gpa), we got good control from non-selective herbicides on broadleaf weeds and grasses 4 inches tall or less. The weed control was the same with flat fan nozzles."

The Turners, Haywood and just two hired hands farm 3,800 acres. The land includes 1,200 acres of rice, part of which is for seed. About 75% of their 1,900 acres of soybeans are Roundup Ready, the majority for seed for Pioneer Hybrid International. With their modest labor force, they have to cover a lot of acres in a day without drift. They have to ensure they'll spray all their crops on time.

"We have a neighbor with 500 acres of watermelons. You can't get Stam, Facet, Roundup or just about any other herbicides on watermelons - they are as sensitive to most herbicides as tomatoes, or more so," Jerry Turner says.

Like many growers with large acreages that need timely spraying, they use a big, fast, high-clearance sprayer to minimize their need for aerial spraying, which is more costly.

"We bought our SpraCoupe 3440 just before the 1999 season. I called Roger (Gipson, the University of Arkansas Clay County Extension agent based at Corning) to ask what kind of nozzle we could get to spray all kinds of application - pre-plant incorporated, pre-emergence and post-emergence herbicides, as well as insecticides," Keith Turner says.

"We didn't want those multiple nozzle bodies with rotating heads with different tips," Jerry says.

Gipson suggested they check out the air-induction nozzle offered by a number of companies. (For more on how this kind of nozzle works, see the sidebar.)

Keith says he found the Greenleaf Technologies TurboDrop® Venturi nozzle that they use on the Internet. "A number of companies make similar ones," he says. "We bought these because they have ceramic orifices, which we wanted for the extra durability. At the time we bought them, they were the only ones of that type we could find in ceramic." Keith says he bought the nozzles on sale at a discount at the Louisville (KY) Farm Machinery Show for $11.50 each.

To get the pattern we wanted, with the proper overlap, we put 36 of them on our 60-foot spray boom," Keith says.

Baldwin says it's worth the investment. "Even though the air-induction nozzles cost more than other kinds of nozzles, they're worth the cost if you figure what just one drift complaint would cost you," he notes.

Gipson likes the nozzles' versatility. He says they work well with a wide range of spray pressures. They spray uniformly large droplets, regardless of the pressure, and that's true even up to 90 to 100 pounds per square inch (psi).

"With these big, fast ground sprayers, you have to run with high pressure to put out the spray volume you want. Another thing I like is you can spray lots of different products with the same tip," Gibson adds.

Keith says they run the nozzles at 70 psi for everything they spray. He says the versatility of the nozzles has met their expectations for adequate spray coverage and level of weed control.

"In rice, we use the same nozzles to apply pre-emergence Command and post-emergence propanil and Facet. In soybeans, we use them for Roundup burndown and over-the-top Roundup in Roundup Ready beans. In conventional soybeans, we use them for pre-plant incorporated spraying of Dual or a Treflan+Canopy tank mix and to spray insecticides such as Scout for soybean pod worm. In wheat the same nozzles spray Harmony Extra+2,4-D for vetch, wild onions and blue cornflower. In corn, we use them to spray a pre-emergence Bicep+atrazine tankmix," Keith says.

In short, he says, the air-induction nozzles fit their diversified crop mix; it's a solution for the difficult spraying conditions they often face amid pressures to be timely and the need to be careful near the herbicide-sensitive watermelons next to their fields.

Big, Droplet-Size 'Air' The Key

How can the big, fast high-clearance sprayers - equipped with air-induction nozzles that run at high speed - put out big droplets at high spray pressures and avoid small droplets that drift away over nearby crops?

"It's a technology that reduces the fine droplets in the spray pattern," says Dennis Gardisser, University of Arkansas Extension ag engineer. "The nozzles are designed to release spray pressure in stages, which results in larger droplets." So the sprayed liquid leaves the nozzle at lower pressure than it enters the nozzle.

"Most air-induction nozzles spray droplets with a volume median diameter (vmd) of 500 to 600 microns," notes Al Womac, University of Tennessee ag engineer." Essentially, what the companies did was convert foaming nozzles so they don't foam so much. However, remember, the more surfactant you use, the more air is mixed in the droplets, which results in more foaming."

The nozzles are designed with two chambers. At the top of the first chamber is the small liquid metering orifice through which the spray mixture shoots into the first chamber, which has a port (venturi) open to the atmosphere.

Gardisser explains the Venturi chamber creates negative pressure, which sucks in outside air, but prevents the liquid from squirting out the side of the nozzle. "As you increase the pressure coming into the chamber, you increase suction within the chamber to pull in the outside air, which forces air and liquid into the second chamber."

At the bottom of the first chamber is an outlet orifice opening into the second chamber, where air mixes with the liquid. The spray leaves the nozzle through a pattern tip that forms large droplets less prone to drift and containing tiny air bubbles.

Marketers of air-induction nozzles claim the droplets, which contain tiny air bubbles, shatter upon impact. This spreads liquid over a wider area than without the air, offering better coverage and less runoff than might be expected with big droplets, but without the potential to drift of droplets that are small when they leave a nozzle.

"The Venturi nozzles do a better job controlling where the droplets land, which results in a more environmentally sound spray job, because we're not allowing fine droplets to be generated," Gardisser says. "But I'm not sure claims of improved efficacy result from the air in the droplets or the changes in droplet-size spectrum."

Womac agrees, saying he's not found data definitively proving the air bubble theory. In any case, he likes air-induction nozzle for herbicides applied where drift could injure crops or vegetation outside the field. "There are some other kinds of nozzles, such as certain flood tips, that also reduce drift."

He also cautions, "With the air induction nozzles, there's a higher coefficient of variation of deposit, which means some areas are hit by higher concentrations of droplets, so you could get some streaking with some chemicals that require more uniform concentrations of droplets. For example, if you're spraying an insecticide with contact activity for which you need uniform deposition on both the top and bottom surfaces of leaves, other kinds of nozzles may do a better job."

Womac adds, "What spray volume are you spraying, what pest and where is it located within the canopy? These are questions to ask yourself."

"I can't think of any application in Arkansas row crops where air induction nozzles don't fit. But you might have to use a smaller size Venturi nozzle to create the droplet size that fits some situations, such as spraying certain insecticides," Gardisser says.