Greenleaf Technologies: Optimizing Sprayers for Top Efficiency ~ AG Retailer

Jim McGaughey, Ag Retailer, March 1997

Improving the performance of chemical application equipment has become a priority for farmers and custom applicators. A new advance in spray technology provides an economical means of optimizing both the sprayer and the applicator's time.

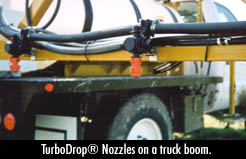

The TurboDrop® Venturi nozzle from Greenleaf Technologies, Covington, LA, will retrofit to any existing spray rig used for the application of pesticides and other agricultural chemicals, the company says.

"A dramatic reduction in drift is probably the most obvious benefit of the nozzle," says Will Smart, company president. "'Most drift reduction nozzles sacrifice coverage. But  the TurboDrop®'s unique design actually allows for improved coverage. Penetration into the crop canopy is also improved with the nozzle, giving it the advantages of air-assist sprayers at an affordable price."

the TurboDrop®'s unique design actually allows for improved coverage. Penetration into the crop canopy is also improved with the nozzle, giving it the advantages of air-assist sprayers at an affordable price."

The heart of the nozzle is the TurboDrop® venturi, which is an air inducing Venturi combined with a mixing chamber. The Venturi creates suction which pulls air into the nozzle through an air inlet. This air is combined with the spray fluid in the mixing chamber. The result from the spray tip is airfilled spray droplets that are double the size produced by conventional nozzles."

The air inside the drops expands once outside the nozzle, accelerating the spray droplets toward the target. The key to good coverage is what happens next. When the air-filled drops hit the target surface, they explode on impact into many small droplets.

Pressure Down, GPA Rates Up

"Because of drift concerns in recent years, spray pressures have gone down and GPA rates have gone up."

"TurboDrop® reverses this trend," Smart says. "'Minimizing GPA rates makes better use of the applicator's time (filling the tank less often) and improves chemical efficacy (chemicals are generally more effective in a more concentrated form)."

The nozzle is designed for operating pressures from 40 to 300 PSI, depending on the application and the type of sprayer. "Because of its wide operating range, farmers can cover multiple rates simply by varying the pressure," Smart says. "This may be the best nozzle to use with sprayer controls."

To precisely control flow rate, the nozzle uses a ceramic metering orifice, which is 10 times harder than stainless steel. This ceramic disc not only provides long life, but also protects the pattern tip and reduces the potential for clogging.

Actually, the TurboDrop® Venturi may be used with most types of conventional spray tips to improve their performance, the company says. It is important, however, to match the two correctly. The spray tip forms the spray pattern, while the Venturi controls the flow rate. The "Pattern" tip needs to be about twice the size of the Venturi in order to accommodate the added air.

Versatile Technology

The experience of Southern grower Jay Hardwick, who farms 5,000 acres of cotton, corn, peanuts, wheat, milo, and soybeans, shows just how versatile this technology is. Hardwick used TurboDrop® for herbicide burndown work, fungicide in peanuts, and insecticide work in cotton.

"Drift was not my driving reason for using the TurboDrop® in cotton," says Hardwick, who matched .the 01 Venturi with a Turbo TeeJet exit tip to spray his insecticide. "Rather it was the dramatic improvement in penetration and coverage which made the nozzle much more cost effective than spraying with a conventional tip." By not having to spray as often, he saved 20 percent on his chemical bill, Hardwick says.

Reduced nozzle clogging and reduced applicator exposure to pyrethroids was an added benefit. "The cumulative effect with TurboDrop® is better use of time, better performance, better efficiency, and less cost per. acre," Hardwick adds.

The Venturi nozzle makes any sprayer much more versatile, Smart says. It reduces downtime due to wind and nozzle clogging, it allows higher driving speeds, and it covers more GPA rates with each individual nozzle size.

"TurboDrop®'s first year in the U.S. proved that its technology has a place in the application market. Monsanto recommended it last year for Roundup applications in corn and milo," Smart adds. "Most importantly, applicators around the country found TurboDrop® extremely effective in applying pesticides and other crop protection chemicals," he concludes.