Reducing Roundup Drift

James L. Griffin, Jeffrey M. Ellis, Curtis A. Jones,

Jonathan D. Siebert, Eric P. Webster and Steven D. Linscombe

Louisiana Agriculture, Vol.46, No.1

Roundup and other glyphosate-containing products are nonselective, postemergence herbicides that control many annual and perennial weeds. Roundup was initially evaluated in the South for preplant weed control in reduced tillage systems, but the role has expanded with the development of herbicide-resistant crops. The glypho-sate-resistance (Roundup Ready) gene was introduced in the United States in soybeans in 1996 and in cotton in 1997.

In 2002, about 80 percent of the soybean and 85 percent of the cotton acreage in Louisiana were planted with Roundup Ready varieties. Because of the diversity of crops grown in Louisiana, it is not uncommon for Roundup Ready crops to be planted near Roundup-sensitive crops. Consequently, the potential for herbicide drift is of great concern. In recent years complaints about Roundup drift have increased.

Most agricultural chemicals used to control pests are liquids sprayed onto plants. Conversion of a liquid into spray droplets and the ultimate fate of the droplets depend on nozzle type, spray pressure, droplet size and environmental conditions. Drift occurs when herbicides are applied under windy conditions or when temperature inversions exist. During a temperature inversion, a layer of air forms at the soil surface that is cooler than the air in the immediate atmosphere. This layer of air captures fine spray droplets that disperse with wind. Temperature inversions are most common at dawn, dusk and when there is no air movement.

Research has shown that off-target movement of herbicides can be somewhere between 1/10 and 1/100 of the applied rate. Even though these rates may be considered sublethal, the response can be q uite severe for suscep-tible crops.

In previous research, drift was simulated by varying herbicide rate with application in a constant spray volume. Although this approach provides an estimate of crop response to the herbicide, it does not simulate what happens under field conditions. In the field, drift from aerial or ground equipment would decrease with movement downwind from the point of application. As water in the spray solution evaporates, the remaining spray droplets would become more concentrated with herbicide and the surfactant. The degree of water evaporation would depend on several variables, which include relative humidity and temperature.

To reduce the potential for drift, herbicide should not be applied when conditions are conducive to off-target movement. However, this is easier said than done, particularly when farm management operations are large and timely herbicide application is critical to weed control. Nozzle selection and droplet size play a critical role in drift management. Use of air induction nozzles (also known as Venturi nozzles) and other drift-reducing nozzles may help to minimize herbicide drift potential. However, because of the larger droplet produced by some of the nozzles, weed control with Roundup may be compromised.

Simulated Drift Studies

Drift rates of Roundup Ultra affected yields of rice and corn but not cotton or soybeans. A 4-ounce rate of Roundup Ultra applied to 2-3 leaf rice reduced yield 83 percent (Table 1), compared to a 2-ounce rate that reduced yield 15 percent. Application to 2-3 tiller rice reduced yields as much as 42 percent. When Roundup Ultra was applied to 6-leaf corn, yield was reduced 78 percent for the 4-ounce, 43 percent for the 2-ounce and 22 percent for the 1-ounce rates (Table 1). When application was delayed to 9-leaf, corn yield was reduced as much as 33 percent.

Cotton maturity was not delayed by drift rates of Roundup Ultra. Some early season injury to cotton and soybeans was observed, but plants were able to recover rapidly and yields were not affected (Table 1).

Spray Volume Studies

When Roundup Ultra was applied at 4 ounces per acre, corn yield was reduced 64 percent when the spray volume was 25 gallons per acre but was reduced 96 percent for the same rate when applied in 3.1 gallons per acre (Table 2). When the 2-ounce per acre rate was appliced, the corn yield was reduced 21 percent when spray volume was 25 gallons per acre but was reduced 88 percent when applied in 1.6 gallons per acre.

A possible explanation for the differences may be related to spray droplet number and herbicide and surfactant concentration in individual spray droplets. For the 3.1 and 1.6 gallon per acre spray volumes, spray droplets would have been more concentrated with herbicide and surfactant compared to the 25 gallon per acre spray volume, even though Roundup Ultra rate per acre was the same. The higher surfactant concentration at the lower spray volumes may have increased uptake of glyphosate into the corn, resulting in more injury.

Yield reductions for soybeans were no more than 18 percent, and differences among spray volumes for the Roundup Ultra rates were not detected (Table 2). Results clearly showed, as was the case in the simulated drift study, that corn is very sensitive to Roundup Ultra. Additionally, the spray volume study indicates that results from traditional simulated drift research, in which dose response is evaluated using a constant spray volume, do not represent what occurs under field conditions and may actually underestimate yield reductions. These findings help explain why field observations of Roundup drift in Louisiana show that crop injury at sublethal rates is greater than what has been observed in our simulated drift and constant spray volume studies.

Drift-reduction Nozzles

The DG TeeJet has a pre-orifice inside the nozzle that reduces internal operating pressure, producing a coarse spray with large droplets. The Turbo TeeJet (flooding-type nozzle) has a turbulence chamber inside the nozzle, providing a coarse spray. The air-induction nozzles (Greenleaf TurboDrop, Greenleaf TurboDrop XL, Greenleaf AirMix and AI TeeJet) each have two orifices, one to meter liquid flow, the other, somewhat larger, to form the spray pattern. In between these two orifices is a jet used to draw air into the nozzle body. In the body of the nozzle, air mixes with liquid, and the resulting spray is low pressure with large, air-filled droplets less prone to drift.

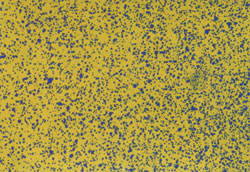

This is an XR TeeJet conventional nozzle with spray

droplet size and coverage shown on a water-sensitive card.

These small droplets are very prone to drift.

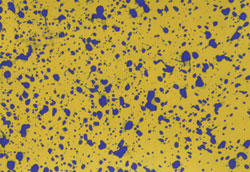

Spray droplet size and spray coverage detected on water-sensitive cards varied among the nozzles evaluated (see photos). The larger spray droplets were noted where the air-induction nozzles were used. Application of Roundup Ultra using the drift-reducing nozzles (air induction along with DG TeeJet and Turbo TeeJet) in a spray volume of 10 gallons per acre provided weed control equal to that of the standard XR TeeJet nozzle.

This is a Greenleaf AirMix nozzle. Note the larger spray

droplet size and coverage on a water-sensitive card.

These large spray droplets are less prone to drift.

The Turbo TeeJet and Greenleaf AirMix nozzles were equally effective in controlling weeds using Roundup Ultra in spray volumes of either 3 or 8 gallons per acre, and control was no less than that obtained with the XR TeeJet nozzle at 10 gallons per acre. There were, however, significant reductions in weed control when the spray volume, regardless of spray nozzle, was reduced below 3 gallons per acre.

Spray Nozzles Play Important Role

Results of these studies indicate the negative effect that Roundup Ultra can have on rice and corn when applied at a rate as low as 1 ounce per acre. Roundup Ultra is effective on grasses, which may explain the greater sensitivity of corn and rice. Cotton and soybeans are more tolerant to Roundup Ultra. However, Roundup Ultra at rates higher than evaluated in this research can be detrimental to cotton and soybeans, too.

Spray nozzles can play an important role in drift management. Drift-reduction nozzles produced larger and coarser droplets when compared with the standard nozzle, and weed control with Roundup Ultra was not compromised. Even though in some cases excellent weed control was obtained with Roundup Ultra when applied at a spray volume of 3 gallons per acre, it is recommended that for consistent weed control under variable environmental conditions, spray volume be at least 5 gallons per acre.

Spray nozzles can play an important role in drift management. Drift-reduction nozzles produced larger and coarser droplets when compared with the standard nozzle, and weed control with Roundup Ultra was not compromised. Even though in some cases excellent weed control was obtained with Roundup Ultra when applied at a spray volume of 3 gallons per acre, it is recommended that for consistent weed control under variable environmental conditions, spray volume be at least 5 gallons per acre.

There is no substitution for use of common sense when applying Roundup or other glyphosate-containing products around sensitive crops. Regardless of whether or not a drift-reduction nozzle is used, spraying glyphosate under windy conditions or during a temperature inversion will increase the odds of off-target movement and the likelihood of crop damage. Based on our research and from observations in the field, our concern is that though visual injury on both corn and rice caused by Roundup drift may be minimal, the negative effect on yield can be significant.

The Louisiana Soybean and Grain Research and Promotion Board provided funds to support this research. James L. Griffin, Professor, and Jeffrey M. Ellis, Curtis A. Jones and Jonathan D. Siebert, all current or former Research Associates, and Eric P. Webster, Associate Professor, Department of Agronomy, LSU AgCenter, Baton Rouge, La.; and Steven D. Linscombe, Director, Southwest Region, Crowley, La. Reprinted with permission from Louisiana Agriculture magazine